Introduction:

- A biogas plant is an artificial system which facilitates the conversion of wastes (organic matter) produced by anaerobic digestion into sustainable energy and fertilizers in an eco-friendly manner.

- Biogas is a renewable energy produced through a bio-chemical process utilizing agricultural waste, manure, sewage, raw materials from the farming sector, paper wastes, animal excrement, and food wastes in the presence of certain types of bacteria.

- It is a mixture of approximately 50-65% methane, 30-40% of CO2, traces of H2, and other gases However, not all types of waste can emit gases with the same composition.

Substrate:

- Plant and animal biomass

- Animal biomass – cattle dung, manure from poultry, goats & sheep slaughter house & fishery wastes

- Agricultural wastes also used

- Vegetable waste

- Poultry droppings

Components:

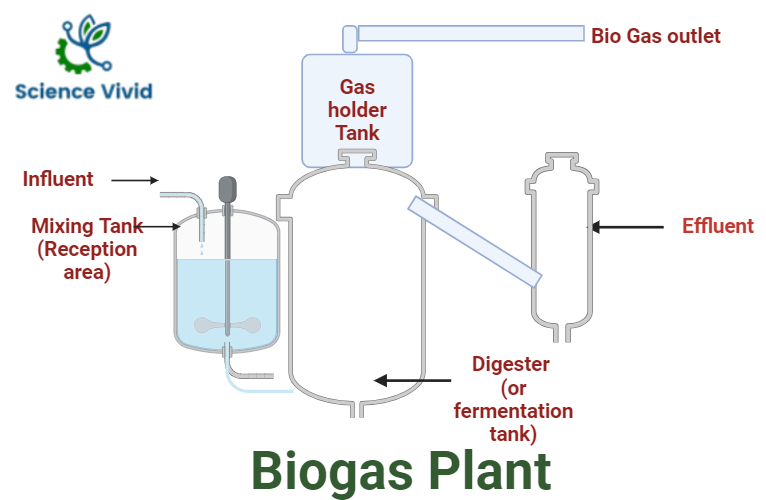

Reception area

- This is the main site in which several types of raw materials are collected in the mixing tank and prepared for anaerobic digestion.

- Different fermentation processes are applied for each type of biomass used. A homogeneous slurry is prepared accordingly after addition of sufficient amounts of water.

- Some of the pre-treatments are employed in order to accelerate fermentation and increase the production of biogas.

A digester (or fermentation tank)

- The inlet pipe is used in order to discharge the substrate which is produced in the reception area into a fermentation tank. Generally, it is built underground and insulated in order to maintain the heating system that is made up of bricks, sand, or cement.

- Likewise, the outlet wall of the inlet chamber is made inclined so that the substrate can easily flow to the digester.

- The digester is an air-tight, sealed, and waterproof container that provides an optimum condition for anaerobic digestion. Furthermore, the agitators promote homogeneous digestion and avoid the production of layers, scum, or silt. Hydrolytic, fermentative bacteria, acidogenic bacteria, acetogenic bacteria, and methanogenic bacteria are employed in order to convert the biomass into a gas. This tank is also fitted with monitoring system in order to monitor the concentration of substrate, products, level of gas, pH, temperature, and pressure.

- Finally, the produced biogas is released into a gas holder and digested slurry (remaining material) from which the biogas is produced is released from the outlet pipe. The gas holder is above the digester whereas the inlet pipe is also at the ground level.

Fig: Components of Biogas Plant

A gas holder

It is an air sealed tank preferably made in steel, provided with a gas outlet monitor that permits the biogas to come out of the system and produce energy and heat. It collects the gas generated during fermentation until the time of utilization.

Benefits from Biogas plants:

- The initial investment is low for the construction of biogas plant.

- Used primarily for cooking and lighting.

- Used in internal combustion engines to power water pumps & electric generators.

- Used as fuel in fuel type refrigerators.

- A source of electricity that generates heat locally

- Sludge – fertilizer.

- Bioremediation (Reduce environment pollution)

Microbiology of Biogas:

Hydrolysis

Biomass is made up of large organic polymers and the complex polymers is hydrolyzed to monomers such as simple sugars, amino acids, and fatty acids in presence of hydrolytic fermentative bacteria such as Clostridium acetobutylicum, C. propionicum, Bacteroids, Butyrvibrio, Selenomonas, Streptococcus spp.

Acidogenesis

Acidogenic bacteria is responsible for the further breakdown of the remaining components which released ammonia, H2, CO2, H2S, shorter volatile fatty acids, carbonic acids, alcohols, as well as trace amounts of other byproducts.

Acetogenesis

Acetogenic bacteria such as Clostridium, Succinomonas, Succinovibrio, Syntrphomonas spp are responsible for further digested phase further digested to acetic acid, carbon dioxide and hydrogen.

Methanogenesis

This is the terminal stage and these components make up the majority of the biogas emitted from the system in which intermediate products of the preceding stages are eventually converted to methane, carbon dioxide, and water using methanogenic bacteria. pH, temperature, nitrogen concentration, C:N ratio, creation of anaerobic conditions are the responsible factors affecting methane formation.